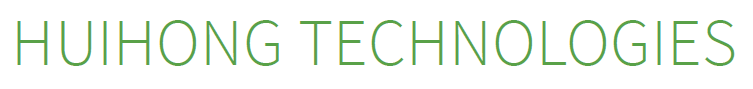

Fiber optic splice trays are an essential component of modern networking and telecommunications infrastructure. These trays are used to hold and protect the delicate fiber optic splices that connect different sections of fiber optic cables.

One of the key benefits of using fiber optic splice trays is their ability to provide a secure and organized method for splicing fiber optic cables. Without the use of splice trays, fiber optic splices may be vulnerable to damage or disruption, which can result in costly downtime and repairs.

In addition to providing protection for fiber optic splices, fiber optic splice trays also help to reduce clutter and improve the overall organization of a fiber optic network. This is especially important in large-scale installations where hundreds or even thousands of fiber optic cables may be in use.

There are several different types of fiber optic splice trays available on the market, each designed to meet the specific needs of different fiber optic installations. Some splice trays are designed to hold a small number of splices, while others can accommodate hundreds of splices in a single tray.

Another important consideration when choosing a fiber optic splice tray is its ability to protect the splices from environmental factors such as temperature and humidity. These factors can have a significant impact on the performance and reliability of fiber optic splices, and it is important to choose a splice tray that can provide adequate protection.

The use of fiber optic splice trays is crucial for the proper installation and maintenance of modern networking and telecommunications infrastructure. By providing a secure and organized method for splicing fiber optic cables, splice trays help to ensure the reliable operation of fiber optic networks and keep downtime to a minimum.

How to properly store and organize fiber optic splices in splice trays

Proper storage and organization of fiber optic splices is essential for maintaining the integrity and reliability of a fiber optic network. Splice trays provide a secure and organized space for splicing and storing fiber optic cables. When used correctly, splice trays can help protect and organize splices, making it easier to identify and troubleshoot any issues that may arise.

To properly store and organize fiber optic splices in splice trays, follow these steps:

1.Choose the appropriate splice tray for your needs. Splice trays come in different sizes and configurations, depending on the number of splices you need to store. Consider the size and type of your fiber optic cables, as well as the amount of space you have available.

2.Follow the manufacturer’s instructions for installing the splice tray. This may involve mounting the tray to a wall or other surface, or securing it in a rack or cabinet.

3.Prepare your fiber optic splices for storage. This typically involves stripping and cleaving the fiber optic cables, then splicing them together using a splicing tool. Be sure to follow the manufacturer’s instructions for your specific splicing tool.

4.Place the spliced fibers in the splice tray. Most splice trays have specific slots or compartments for storing splices. Be sure to follow the manufacturer’s recommendations for the number and placement of splices in each compartment.

5.Close and secure the splice tray. This may involve closing a hinged lid or securing a cover with screws or clips.

6.Label the splice tray. It is important to label each splice tray with the appropriate information, such as the date of the splice, the type of fiber optic cables used, and the location of the splice within the network.

By following these steps, you can properly store and organize your fiber optic splices in splice trays, helping to ensure the integrity and reliability of your fiber optic network.

The different types of fiber optic splice trays available, including tray capacity and mounting options

Splice trays are an essential component of any fiber optic network, allowing for the organization and protection of fusion spliced fibers. These trays are designed to hold individual fibers or mass fusion spliced fibers, and are typically installed within fiber optic enclosures and patch panels.

One of the key advantages of splice trays is their compact and lightweight design, making them easy to install and handle. They are available in a variety of sizes and configurations, with splice holding chips that can accommodate anywhere from 12 to 24 fibers. Some splice trays also come with cover options to provide additional protection for the spliced fibers.

Splice trays are pre-configured for standard heat shrink fusion splices, ensuring that they are ready to use right out of the box. However, it is important to note that not all splice trays are created equal. It is important to choose a splice tray that is specifically designed for your fiber optic network, as it will ensure optimal performance and protect your investment in the long term.

Splice trays are an essential part of any fiber optic network, providing a safe and organized way to hold and protect fusion spliced fibers. Whether you are installing a new fiber optic network or upgrading an existing one, splice trays should be a key consideration in your planning and design process.

The importance of maintaining proper fiber optic splice protection in splice trays

When it comes to fiber optic networking, physical security is a crucial consideration. After all, your fiber optic cables are the backbone of your network, carrying important data and communications from one point to another. If these cables are damaged or compromised, it can have serious consequences for your business or organization.

One simple yet effective way to ensure the physical security of your fiber optic cables is by using fiber optic splice trays. These trays provide a protective space for your fusion splices, keeping them safe from potential damage or tampering. In addition to providing security, fiber optic splice trays also help to organize your cables, making it easier to manage and maintain your network.

But what exactly is a fiber optic splice tray and how does it work? Simply put, a fiber optic splice tray is a specialized container that holds and protects fusion splices, which are the points where two or more fiber optic cables are joined together. These splices are essential for connecting different sections of fiber optic cable and allowing data to flow freely between them.

Fiber optic splice trays come in a variety of sizes and configurations to suit different needs and applications. Some are designed for use in outdoor environments, while others are suitable for indoor use. Some trays are made to hold a small number of splices, while others are capable of holding hundreds.

When installing a fiber optic splice tray, it’s important to follow proper procedures and guidelines to ensure the safety and integrity of your splices. This may include using proper splicing techniques, following manufacturer instructions, and using the correct tools and equipment.

In addition to providing physical security and organization, fiber optic splice trays can also help to improve the overall performance and reliability of your fiber optic network. By protecting your splices from external threats and ensuring that they are properly organized and maintained, you can help to ensure that your network is running smoothly and efficiently.

Fiber optic splice trays are an essential component of any thriving fiber optic network. By providing a protective space and helping to organize your fusion splices, these trays help to ensure the physical security and reliability of your network. By investing in high-quality splice trays and following proper installation and maintenance procedures, you can help to ensure the long-term success of your fiber optic network.

Best practices for installing fiber optic splice trays in fiber optic splice closures

Installing fiber optic splice trays in fiber optic splice closures is an important task that requires careful planning and attention to detail. By following best practices, you can ensure that your installation is efficient, reliable, and safe.

1.Plan the layout of your splice tray carefully. Consider the number of fibers you need to splice, the size of your splice closure, and the amount of space you have available. It is important to leave enough room for expansion, as you may need to add more fibers in the future.

2.Use fiber optic splice organizers to keep your fibers organized and protected. These organizers allow you to neatly arrange your fibers and prevent them from becoming tangled or damaged.

3.Follow proper handling procedures for your fibers. Be sure to avoid bending the fibers too sharply, as this can cause them to break. Also, be sure to handle them gently to prevent damage to the delicate glass or plastic fibers.

4.Use appropriate tools for the job. Splicing fibers requires specialized tools such as fiber optic strippers, cleavers, and splicing machines. Be sure to use the correct tools for the job to ensure a successful splice.

5.Test your splices before closing the splice tray. This will allow you to detect any problems or issues before the tray is sealed, making it easier to fix any issues that may arise.

By following these best practices, you can ensure that your fiber optic splice tray installation is successful and reliable.

The role of splice trays in fiber optic cable management and organization

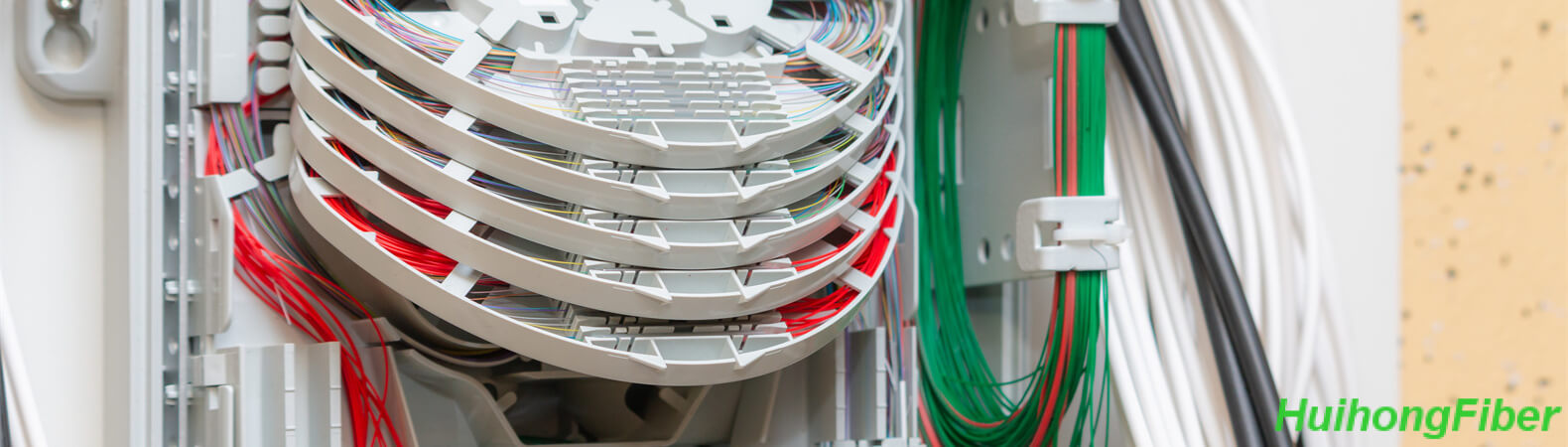

Splice trays are an essential component of fiber optic cable management and organization. These trays provide a secure and organized space for splicing together the fibers of different cables, which is necessary for establishing a connection between them.

Splice trays are typically used in fiber optic distribution frames (ODFs) or fiber optic enclosures. These structures provide a central location for organizing and splicing together the fibers of multiple cables, making it easier to manage and maintain the network.

The use of splice trays helps to protect the spliced fibers from damage and allows for easy access in case any maintenance or repairs are needed. They also help to reduce the risk of fiber optic cables becoming tangled or disorganized, which can cause disruptions in the network.

The impact of temperature and humidity on fiber optic splices stored in splice trays

Fiber optic splices, which are used to join two fiber optic cables together, are sensitive to environmental factors such as temperature and humidity. These factors can have a significant impact on the performance and reliability of the splice.

When fiber optic splices are stored in splice trays, they are typically exposed to a range of temperature and humidity levels. High temperatures can cause the splice to become brittle and weaken the mechanical integrity of the splice. This can lead to an increased risk of the splice breaking or failing.

Similarly, high humidity levels can cause water vapor to condense on the splice, leading to the formation of water droplets. This can cause the splice to become contaminated, which can lead to increased attenuation (light loss) and decreased signal quality.

To minimize the impact of temperature and humidity on fiber optic splices, it is important to store the splices in a controlled environment. This may involve the use of a splice tray that is designed to regulate temperature and humidity, or the use of a splice tray that is stored in a temperature-controlled room.

In addition to controlling the environment in which the splices are stored, it is also important to regularly inspect the splices for signs of damage or degradation. This can help to ensure that the splices are in good working order and can be used with confidence.

The maintenance and inspection of fiber optic splice trays to ensure proper performance and reliability.

Fiber optic splice trays are an essential component of any fiber optic network, providing a secure and organized method for splicing and managing fiber optic cables. Proper maintenance and inspection of these trays is crucial to ensure their proper performance and reliability.

The first step in maintaining fiber optic splice trays is to keep them clean and free of debris. Dust, dirt, and other contaminants can accumulate on the tray and cause damage to the splices or interfere with the transmission of light. To prevent this, the tray should be regularly dusted and wiped down with a clean, dry cloth. If the tray is particularly dirty, it may be necessary to use a mild cleaning solution and a soft, lint-free cloth to gently scrub the tray and remove any stubborn dirt or grime.

In addition to keeping the tray clean, it is also important to regularly inspect the splices to ensure they are secure and free from damage. Any loose or damaged splices should be promptly repaired or replaced to prevent disruptions to the fiber optic network. It is also a good idea to inspect the tray itself for any damage, such as cracks or breaks, which could compromise the integrity of the splices.

Another important aspect of maintaining fiber optic splice trays is organizing the fibers in a clear and logical manner. This not only makes it easier to identify and access individual fibers, but also helps prevent accidental damage to the fibers. When organizing the fibers, it is important to use suitable fiber management products, such as fiber optic organizers and cable ties, to keep the fibers organized and secure.

Finally, it is important to follow all manufacturer recommendations and guidelines when performing maintenance and inspection on fiber optic splice trays. This includes using the proper tools and equipment, as well as following all safety precautions to prevent accidents and injuries.

By following these simple maintenance and inspection steps, it is possible to ensure that fiber optic splice trays are functioning properly and reliably, helping to keep your fiber optic network running smoothly.

Plastic splice trays and Aluminum splice trays from Huihongfiber

Huihongfiber is a leading manufacturer of fiber optic splice trays, with a wide range of options to choose from. Whether you need a tray with 12 fibers or one with 24 fibers or even more, Huihongfiber has you covered.

What sets Huihongfiber apart is the materials they use for their splice trays. They offer both plastic and aluminum options, allowing customers to choose the one that best fits their needs and budget. Both materials have their own unique benefits, so it’s important to consider which one is right for you.

Plastic splice trays are lightweight and easy to install, making them a popular choice for many customers. They are also more affordable than aluminum trays, making them a good option for those on a budget.

Aluminum splice trays, on the other hand, offer superior durability and protection for your fiber optic splices. They are more resistant to damage and can withstand harsh environments, making them a great choice for outdoor or industrial applications.

No matter which material you choose, Huihongfiber’s fiber optic splice trays are of the highest quality and will ensure your fiber optic connections are secure and protected. So if you’re in need of a fiber optic splice tray, be sure to check out Huihongfiber for all your splicing needs.