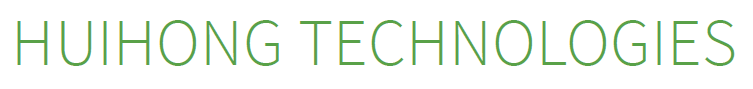

A fiber optic patch panel is a device used in fiber optic networks to connect and manage fiber optic cables. It typically includes a number of ports, each of which can be used to connect a single fiber optic cable. Patch panels are used in both residential and commercial fiber optic networks to provide a convenient and organized way to connect and disconnect cables as needed. They are also used to protect the delicate fiber optic connectors from damage and to provide a central location for monitoring and troubleshooting the network.

Huihongfiber is a leading manufacturer of fiber optic patch panels, offering a wide range of products to meet the needs of various industries. The company’s patch panels are used by telecom operators, data centers, and other organizations to manage and organize their fiber optic cabling.

In addition to its standard patch panels, Huihongfiber also offers OEM and customized solutions to meet the special needs of different customers. This flexibility allows customers to choose the exact specifications and features that they need, such as different port counts, different fiber types, and different color codes.

Huihongfiber is a trusted name in the fiber optic industry, known for its high-quality patch panels that are versatile, durable and customizable to meet different customers’ needs. Whether you are a small business or a large corporation, Huihongfiber has a patch panel solution that will work for you.

The different types of fiber optic patch panels available

Fiber optic patch panels are an essential component in any fiber optic network. They provide a convenient and organized way to connect, manage, and maintain the fiber optic cables that run throughout a building or campus. There are several different types of fiber optic patch panels available on the market, each with their own unique features and benefits.

Wall-mounted patch panels are designed to be mounted on a wall and are typically used in residential or small business environments. These patch panels are compact and easy to install, making them a popular choice for those with limited space. They also come with a variety of adapter options and can support a variety of connector types, such as LC, SC, and ST.

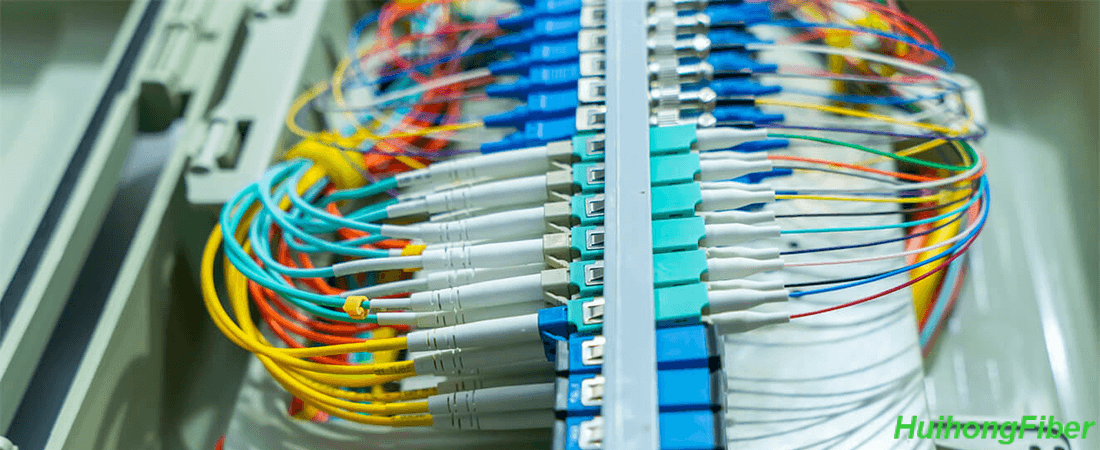

Rack-mounted patch panels are designed to be mounted on a rack and are typically used in larger commercial or industrial environments. These patch panels are larger and more robust than wall-mounted patch panels and can support a higher density of connections. They also come with a variety of adapter options and can support a variety of connector types, such as LC, SC, and ST.

there are several different types of fiber optic patch panels available on the market, each with their own unique features and benefits. Whether you are working in a residential or small business environment, or a larger commercial or industrial environment, there is a patch panel that will meet your needs. Consider the space you have available, the number of connections you need to make, and the types of connectors you will be using when choosing the right patch panel for your network.

Understanding the basic components and design of a fiber optic patch panel

A fiber optic patch panel is a device that is used to organize and manage the connections between fiber optic cables. It is an essential component in any fiber optic network, as it allows for the easy installation, organization, and maintenance of fiber optic cables.

The basic components of a fiber optic patch panel include the panel itself, the fiber optic adapter plates, and the fiber optic patch cords. The panel is typically made of metal and is designed to hold the adapter plates and patch cords in place. The adapter plates are used to connect the fiber optic cables to the patch panel, while the patch cords are used to connect the panel to other devices in the network.

The design of a fiber optic patch panel is relatively simple, but it is critical that it is done correctly to ensure that the network functions properly. The panel should be designed to accommodate the specific type of fiber optic cables that will be used in the network, as well as the number of cables that will need to be connected. The adapter plates and patch cords should also be carefully chosen to ensure that they are compatible with the panel and the other devices in the network.

One of the key considerations when designing a fiber optic patch panel is to ensure that it is easy to access and maintain. This is particularly important in large networks where there are many cables and devices that need to be connected. To make maintenance easier, the panel should be designed with a clear labeling system and should be located in a central location that is easily accessible.

In addition to the basic components and design, there are also different types of fiber optic patch panels. One common type is the rack-mountable patch panel, which can be mounted on a standard 19-inch rack. Another type is the wall-mountable patch panel, which can be mounted on a wall or other flat surface.

Outdoor fiber patch panels

Outdoor fiber patch panels are a crucial component in any fiber optic network that needs to be installed in outdoor environments. These patch panels are specifically designed to withstand the harsh conditions of the outdoors, such as rain, snow, dust, and wind. This ensures that the fiber optic connections remain stable and secure, even in the most adverse weather conditions.

Outdoor fiber patch panels are typically constructed from materials that are highly durable and resistant to corrosion. Fiberglass, steel, and aluminum are common materials used in the construction of these patch panels. These materials provide excellent protection against the elements and help to prolong the life of the patch panel.

One of the most important considerations when installing outdoor fiber patch panels is the NEMA rating. The NEMA rating is a standard that defines the types of environmental protection that the patch panel enclosure will provide. A NEMA 4 rating or higher is recommended for outdoor fiber patch panels. This rating indicates that the enclosure is designed to protect against water, dust, and other environmental factors.

Outdoor fiber patch panels can be installed in a variety of ways, depending on the specific needs of the network. They can be mounted on a wall or pole, making them versatile and suitable for a wide range of applications. This allows for easy installation and maintenance, and provides a secure and stable connection for the fiber optic cables.

Fiber optic patch panels with DIN rails

DIN fiber optic patch panels are a popular choice for industrial installations where a DIN rail is the preferred type of mounting solution. These patch panels are designed to be small and lightweight, making them suitable for the unique demands of industrial environments.

The most common type of DIN rail in the United States is the T-35 DIN rail, which is in accordance with the IEC/EN 60715 Standard. This standard ensures that the DIN rail is of a consistent size and shape, allowing for a uniform and secure fit for DIN-mountable patch panels.

DIN fiber optic patch panels will typically include a DIN clip, which attaches to the DIN rail and allows for quick installation and removal. This feature is particularly useful in industrial settings, where equipment and systems may need to be frequently accessed and maintained.

The compact size and lightweight design of DIN fiber optic patch panels make them ideal for industrial installations where space is at a premium. They are also designed to be durable and withstand the harsh conditions often found in industrial environments. Additionally, these patch panels are designed to be easy to use and maintain, which further reduces the need for specialized maintenance and technical support.

Installation of fiber optic patch panels without fusion splicing trays

Direct termination of fiber optic patch panels refers to the process of installing a fiber connector directly onto the bulk fiber cable. This method eliminates the need for splice trays, as the cables are terminated directly with fiber connectors.

The direct termination process begins by cutting back the cable and separating the individual strands. A connector is then installed directly on the end of each fiber strand. This process is relatively time-consuming, as it requires the use of epoxy and polishing the connectors to ensure proper alignment and a secure connection.

Direct field termination is typically only used in specialized applications where limited space is available, making splicing not possible. It is also more common when the bulk fiber cable is pre-ordered with a factory-performed termination and installed with connectors already in place.

In contrast, when a splice tray is used, the bulk fiber cable is cut and spliced to a connector that is then inserted into the tray. This method is less time-consuming and can be used in situations where a large number of fibers need to be terminated.

Installation of fiber optic patch panels with fusion splicing

Fiber optic patch panels are an important component in any fiber optic network. They provide a central location for connecting, organizing, and protecting fiber optic cables. One of the most common methods for terminating fiber optic cables is through the use of fusion splicing. This process involves using heat to join two fibers together, creating a permanent connection.

When fusion splicing is used, it is necessary to use splice trays or chips to hold the fibers in place while the splicing process is completed. These trays or chips are specifically designed to hold the fibers in place during the splicing process and protect them from damage.

The bulk fiber cable will be joined to a short length of matching fiber where the connectors have been pre-installed, polished, and tested at the factory (fiber pigtail). This is known as a “pigtail splice.” The pigtail splice is a quick process for a trained technician and the most common method for field termination.

When selecting a fiber patch panel for use with fusion splicing, it is important to ensure that the panel supports the use of splice trays or chips. Many patch panels are designed specifically for use with fusion splicing and include built-in splice trays or chips.

If the cable will be directly terminated, it will not require splice trays. However, if it is to be fusion spliced to fiber pigtails, it will require the use of splice trays. In order to select a suitable patch panel, it is essential to determine what type of fiber break-out will be performed.

Commonly used type of fiber optic connectors used on fiber optic patch panels

Fiber optic patch panels are an essential component in any fiber optic network. They provide a central point of connection and organization for all the fiber cables in a network. One important aspect of fiber optic patch panels is the type of fiber optic connectors used. In this article, we will discuss the commonly used types of fiber optic connectors and their uses in fiber optic patch panels.

The first type of connector we will discuss is the ST connector, . This is an older style connector that is most commonly used with Multi-mode (OM1) fiber cable. The ST connector is easy to install and has a simple design, making it a popular choice for many applications.

The next type of connector is the SC connector, also known as the “Square Connector.” This is another older style connector that is most commonly used with singlemode fiber cable. The SC connector is known for its durability and reliability, making it a popular choice for many applications.

The LC connector, also known as the small form connector, is a popular choice where there is a high strand count since they are a smaller form factor. These connectors are the most popular style connector on the market today and are widely used for all types of fiber. The LC connector’s small size makes it a popular choice for high-density applications where space is limited.

FC is most commonly used with single mode fiber. The FC connector is known for its precision and accuracy and is often used in high-performance applications.

When selecting a connector for a fiber optic patch panel, it is important to consider the mode of the fiber and the connector type to be used in the field. Each connector style has its own advantages and disadvantages and should be chosen based on the specific application. Once the mode of fiber and the style of connector have been selected, the appropriate color code can be identified. For SC and LC connectors, the adapter and the connector will be color-coded to represent the type of fiber being used. For ST and FC connectors, the dust cap is used to represent the mode of fiber.

Troubleshooting and maintaining a fiber optic patch panel

Troubleshooting and maintaining a fiber optic patch panel is important for ensuring that your network is running smoothly. By understanding the common problems that can occur, you can take steps to prevent and resolve issues and keep your network running at optimal performance. Regular maintenance and inspection will help prolong the life of the patch panel.

1.Loss of signal: One of the most common problems that can occur with fiber optic patch panels is a loss of signal. This can be caused by a variety of issues, such as a loose connector, a dirty or damaged connector, or a problem with the fiber itself. To troubleshoot this issue, start by checking all of the connectors to ensure that they are securely seated and free of dirt or damage. If this does not resolve the problem, you may need to test the fiber for breaks or other issues.

2.Interference: Another common issue that can occur with fiber optic patch panels is interference from other equipment or sources. This can be caused by electromagnetic interference (EMI) or radio frequency interference (RFI). To troubleshoot this issue, you may need to reposition the patch panel or other equipment to minimize the interference. You can also use shielded cables and other EMI/RFI protection devices to minimize interference.

3.Corrosion: Fiber optic patch panels are vulnerable to corrosion, which can cause damage to the connectors and fibers. To prevent corrosion, it is important to keep the patch panel clean and dry and to use a protective cover if the patch panel is located in an area with high humidity or other environmental factors.

4.Maintenance: Regular maintenance is essential to ensure that your fiber optic patch panel is functioning properly. This includes cleaning the connectors, inspecting the fibers for damage, and testing the signal strength. It is also important to replace any damaged or worn components.