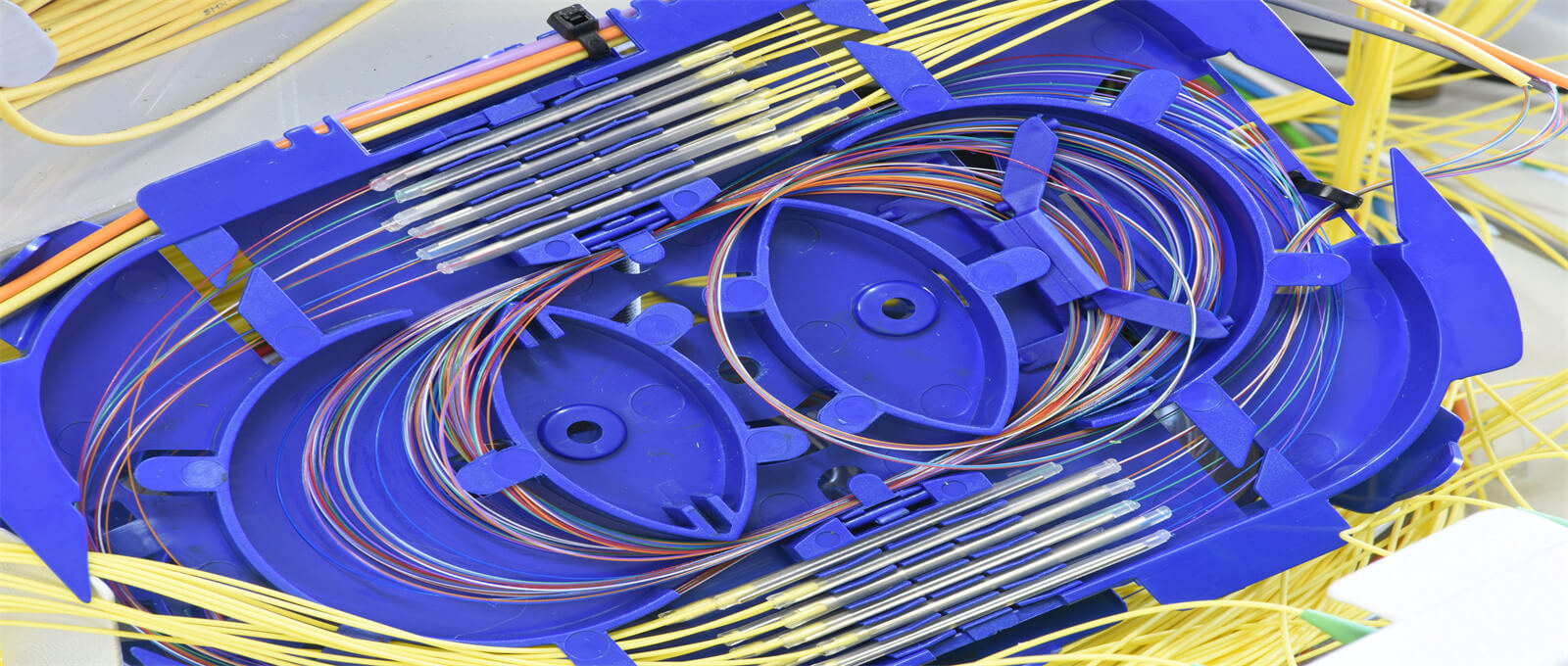

Fiber optic splice sleeves are typically made of heat-shrinkable plastic or stainless steel, and come in various sizes and shapes to accommodate different types of fiber optic cables and splicing techniques. Single-fiber splice sleeves are designed for use with individual fibers, while multi-fiber splice sleeves are used for splicing multiple fibers at once. Ribbon splice sleeves are used for splicing ribbon fiber optic cables, which consist of several parallel fibers bundled together.

The main function of a fiber optic splice sleeve is to provide physical protection for the spliced fibers. When two fibers are spliced together, they are usually held in place by a small piece of adhesive and covered with a protective jacket. The splice sleeve is then placed over the spliced fibers and heat-shrunk to fit snugly around them, providing an additional layer of protection against physical stresses and contaminants.

In addition to providing physical protection, fiber optic splice sleeves also play a critical role in maintaining the integrity of the fiber optic connection. Properly installed and maintained splice sleeves help to reduce signal loss and ensure the reliable transmission of data over long distances.

fiber optic splice sleeves are an essential component of any fiber optic network, and play a vital role in ensuring the reliable and efficient operation of these systems.